Line Pipes

Description

At Tastec Industrial Est., we supply a comprehensive range of line pipes engineered for the safe and efficient transportation of fluids across various industries. Our line pipes are manufactured to meet international quality standards, ensuring reliability, durability, and resistance to pressure, corrosion, and environmental stress.

We offer specialized line pipes in the following categories:

- Water and Drain Line Pipe

Designed for municipal, industrial, and infrastructure projects, our water and drain pipes ensure long-lasting performance and leak-free conveyance of water and wastewater. - Oil Line Pipe

Built for strength and corrosion resistance, our oil line pipes are ideal for transporting crude oil and refined petroleum products in both upstream and downstream operations. - Gas Line Pipe

Engineered to handle high-pressure applications, our gas line pipes ensure the safe transmission of natural gas and other gaseous fuels over long distances.

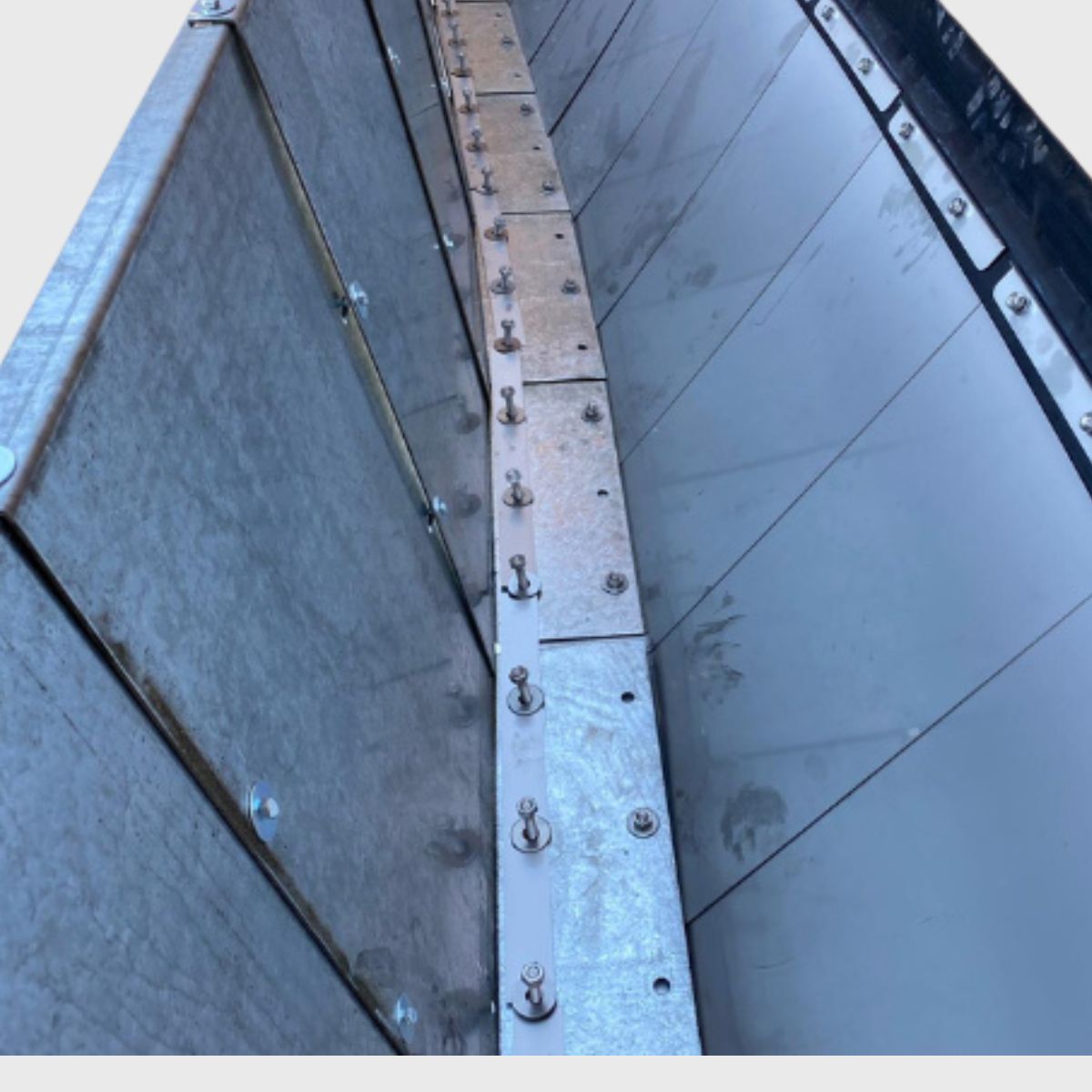

Line Pipe Coatings

At Tastec Industrial Est., we offer a variety of advanced coatings to enhance the durability and corrosion resistance of our line pipes. These coatings are essential for extending the service life of pipelines in demanding environments.

- Fusion Bonded Epoxy (FBE) Coating

FBE is a durable coating commonly used in pipeline construction. It offers strong adhesion and excellent corrosion resistance, suitable for temperatures from -30°C to 100°C. It also resists UV damage and supports directional drilling in different soil types. - Three-Layer Polyethylene (3PE) Coating

3PE features a three-layer structure: epoxy primer, adhesive, and a polyethylene top layer. This combination offers strong corrosion protection, mechanical strength, and resistance to temperatures up to 70°C, depending on the density of polyethylene used. - Three-Layer Polypropylene (3PP) Coating

3PP includes a fusion-bonded epoxy base, adhesive middle layer, and a polypropylene top layer. It provides excellent all-around protection and chemical resistance, ideal for harsh operating conditions and long-term pipeline performance. - Epoxy Coal Tar Coating

Made from epoxy resin and coal tar, this coating forms a strong chemical-resistant barrier. It protects against acids, alkalis, and salts, and can even self-repair minor cracks or surface damage, maintaining pipe integrity. - Silicone Coating

Silicone coatings are used where high-temperature resistance is needed. They offer corrosion protection, waterproofing, insulation, and can withstand temperatures up to 600°C—ideal for pipelines carrying hot fluids. - Internal Coating

Internal pipe coatings reduce corrosion, prevent scaling, and improve flow efficiency. These coatings protect the inner surface from chemical damage while minimizing resistance and improving fluid transport performance.

Reviews

There are no reviews yet.